Products

![[CG]TH20EIII-2EV(TACT-IV)-min](https://idealplastics.com/wp-content/uploads/2023/06/CGTH20EIII-2EVTACT-IV-min-768x543.jpg)

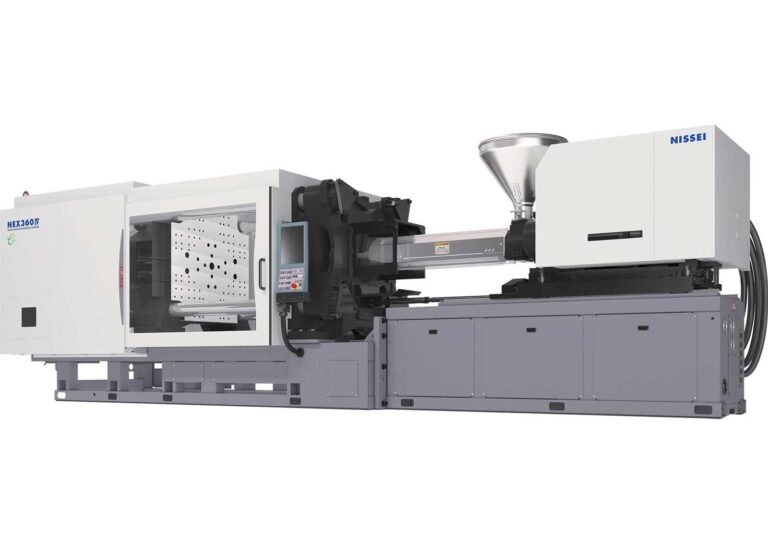

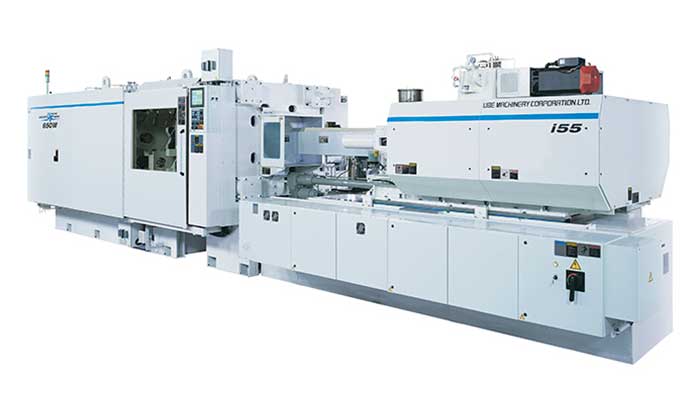

Nissei Plastic Industrial Company, Ltd. is the world leader in injection molding technology with over 140,000 machines in the field. Nissei is focused on providing injection molding machines with the highest technological innovations and is accepted by the industry as the leader, setting the standards. They deliver the highest quality injection machines.

- Hydraulic high precision injection molding machines from 7-1440 tons

- Electric all servo molding machines from 15-500 tons

- Two material injection molding machines

- Vertical clamp machines for insert molding

- Ultra-high speed injection machines for thin wall applications

- Special purpose machines for rubber, LIM, ceramic and metal molding

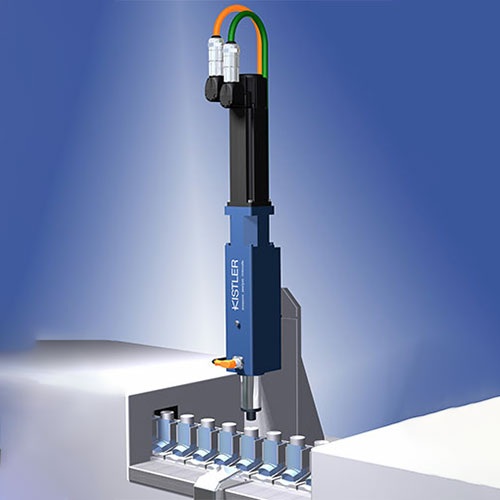

Kistler Instrument Corporation develops measurement solutions consisting of sensors, electronics, systems and services. Kistler offers integrated solutions by supporting all steps of networked, digitized production. The systems Kistler provides ensure maximum process efficiency and profitability in the smart factories of the next generation.

- Complete selection of dynamic sensors measure injection molding cavity pressure, assembly forces and torque in manufacturing processes

- Enhanced transparency in networked injection molding production and process control with ComoNeo

- In-process monitoring of joining and assembly processes focusing on product quality and process reliability with maXYmos BL/TL

- Resource optimization through Integrated process control and monitoring with electromechanical NC joining systems cut energy costs, increase automated system utilization and production efficiency

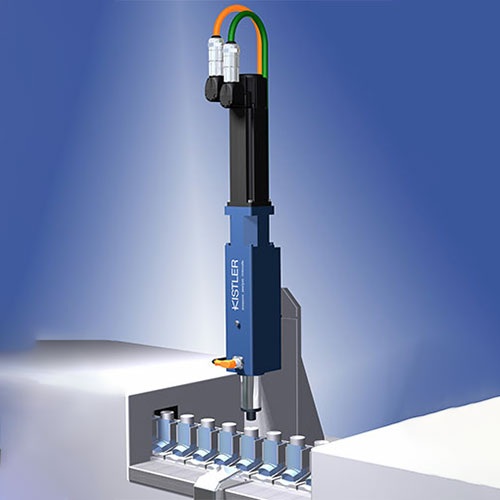

Kistler Instrument Corporation develops measurement solutions consisting of sensors, electronics, systems and services. Kistler offers integrated solutions by supporting all steps of networked, digitized production. The systems Kistler provides ensure maximum process efficiency and profitability in the smart factories of the next generation.

- Complete selection of dynamic sensors measure injection molding cavity pressure, assembly forces and torque in manufacturing processes

- Enhanced transparency in networked injection molding production and process control with ComoNeo

- In-process monitoring of joining and assembly processes focusing on product quality and process reliability with maXYmos BL/TL

- Resource optimization through Integrated process control and monitoring with electromechanical NC joining systems cut energy costs, increase automated system utilization and production efficiency

Star Seiki Co. Ltd. has been a leader for over 50 years in automatic unloading robots for the injection molding industry. With over 160,000 robots shipped globally Star Seiki Co. Ltd has constantly endeavored to manufacture quality robots that contribute to increased automation, reliability and higher efficiency wherever companies are engaged in production activities.

- Sprue Pickers, Unloading Robots, Automation Systems

- Peripheral Automation Systems

- In-Mold Labeling System

- Pallet Changers

- Peripheral Equipment

- End of Arm Tooling (EOAT) and Chucking parts

Regloplas is a World Leader in Process Cooling and Temperature control.

- Complete series of temperature control units for injection molds, extruders, rollers and other applications.

- Pressurized water units up to 446 °F & Oil units up to 660 °F.

- Air-cooled & Water-cooled Chillers.

- RegloChill free cooling systems and other maximum energy saving “Green” cooling technologies.

Regloplas is a World Leader in Process Cooling and Temperature control.

- Complete series of temperature control units for injection molds, extruders, rollers and other applications.

- Pressurized water units up to 446 °F & Oil units up to 660 °F.

- Air-cooled & Water-cooled Chillers.

- RegloChill free cooling systems and other maximum energy saving “Green” cooling technologies.

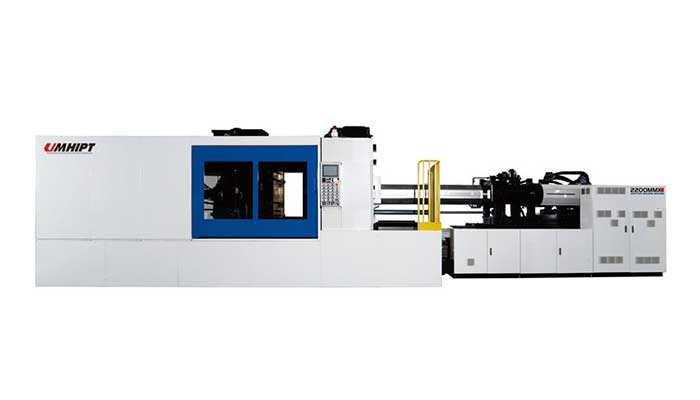

UBE Machinery is the recognized world leader in the production of Large Injection Molding Machines. UBE Machinery manufactures some of the world’s most energy efficient and repeatable Injection Molding Machines in four platforms. All four platforms can be single injection or multiple injection for multiple colors or multiple materials. UBE Injection Molding Machines easily adapt to your many special processes or your custom application.

- All servo electric molding machines from 500-3300 tons

- Hydraulic toggle molding machines from 720-7000 tons

- Two platen hydraulic and electric molding machines from 1000-4000 tons

- Special purpose controlled foam applications

- Special low pressure molding process

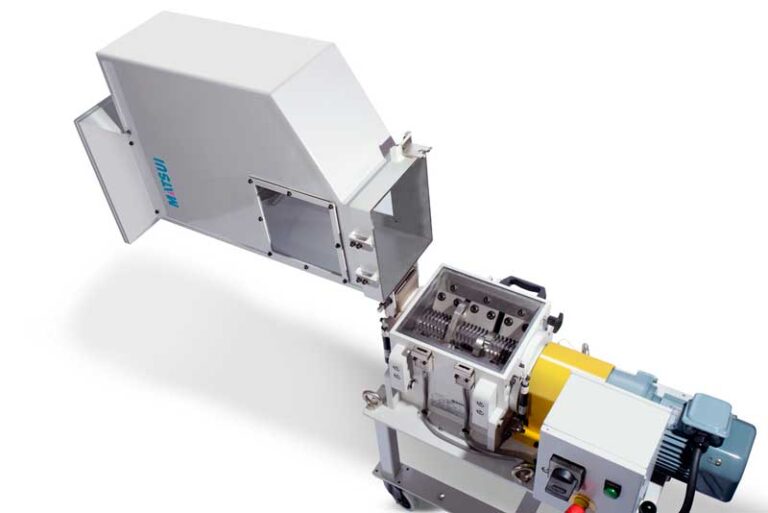

Founded in Japan in 1912, Matsui is a worldwide leader of innovative plastics-processing equipment. Their innovative designs offer real solutions to difficult processing issues- while also creating value to their customer’s products. Matsui’s flagship resin dryer model “MJ6-i” sets the industry-standard for energy-savings, dependability and quality. Matsui’s other products include slow-speed granulators, loaders, mold-temp controllers, and blenders. Matsui’s products eliminate many hurdles in plastics processing: material-moisture, cosmetic defects, contamination, wasted material, blending inaccuracy, static, and most importantly- machine downtime.

The highest quality, state of the art desiccant dryers, low speed granulators, and temperature control units.

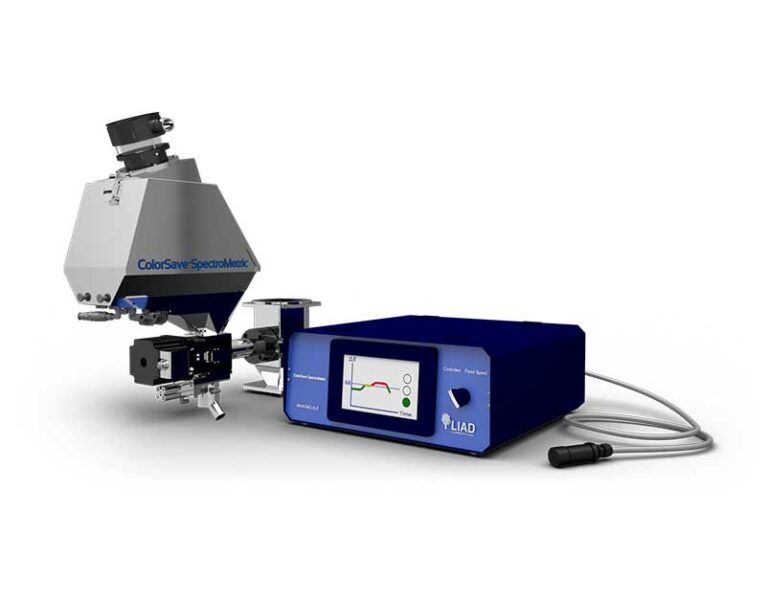

LIAD Smart equipment from Ampacet includes patented blending, dosing and color management technology. LIAD Smart technologies help customers improve production efficiencies, reduce color costs and waste, and achieve sustainability goals.